Early Years

Following

a fire at their former premises at Evesham, the two Foster brothers

set up a new mill and warehouse at Gloucester in 1862 to take advantage

of direct access by sea-going ships. Batches of imported linseed

and cotton seed were crushed, heated and then pressed to extract

the oil, and the residue was sold as cattle cake. The products were

mainly sent out by rail from a siding adjoining the mill. In the

early years, they had about ten employees.

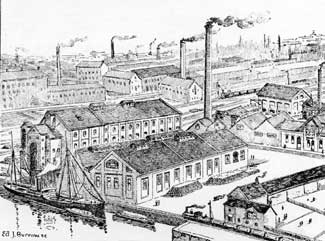

Expansion Expansion

A

major expansion of the premises was carried out in 1891-93 to provide

more milling capacity and warehouse space with a detached boiler

house and a tank house to the east. The output capacity was 600

tons per week, and the workforce increased to over 100, including

some working shifts. Working conditions were not pleasant due to

the heat applied before pressing. In 1899, the business joined with

sixteen other similar firms around the country to form British Oil

& Cake Mills Ltd (known as BOCM).

Another

phase of expansion took place in 1910, including the installation

of a second mill and a de-odorising plant in the eastern part of

the premises, and the capacity rose to 1000 tons per week. In the

1920s, a large shed was erected on the north side of Monk Meadow

Dock to contain oil storage tanks, and the oil was transferred from

the main site by a small tanker barge. In 1925 BOCM was taken over

by Lever Brothers, but the mill at Gloucester continued to be managed

by members of the Foster family until 1945.

Raw Materials and Products

During

the 1920s and 30s, Foster Bros mainly processed linseed (from Argentina,

India and Canada), cotton seed (from Egypt, Bombay and Greece) and

groundnuts (from the west coast of Africa). Most of this material

came by large ship to Sharpness and then by barge to Gloucester,

although some was brought round the coast from Hull by steamer.

The word soon spread when a barge containing groundnuts arrived,

and local lads became experts at collecting handfuls when the firm's

watchman was not looking.

Much

of the linseed oil was sold to paint and varnish manufacturers and

some was used in making linoleum. Cotton seed oil was sold for fish

frying and soap making, and groundnut oil for making margarine.

It was all sent out in barrels made on the premises. Much of the

residual cake was sold as slabs direct to farmers, while some was

mixed with grain and certain additives to produce a range of balanced

animal feeds sold in hessian sacks.

End of Oil Seed Crushing

In

the early 1950s, BOCM installed a big new oil extraction plant at

Avonmouth, using a continuous process rather than the previous batch

operations. This led to the closure of the mill at Gloucester c1955,

and the building was later sold to West Midlands Farmers. At the

same time the Monk Meadow building was converted to a distribution

depot for products made at Avonmouth. However, following the development

of the motorway network and the opening of the Severn Bridge, the

need for the distribution depot at Monk Meadow declined as customers

could readily collect from Avonmouth, and the depot closed in the

mid 1970s.

Sources: Glos Chron 26 Jul 1862, 3 Sep 1910, 3 Feb 1923; Glo

Jnl 21 May 1892; Glos Coll JV 13.1, JR 13.8, NQ 15.8; memories of

former employees. |

Expansion

Expansion